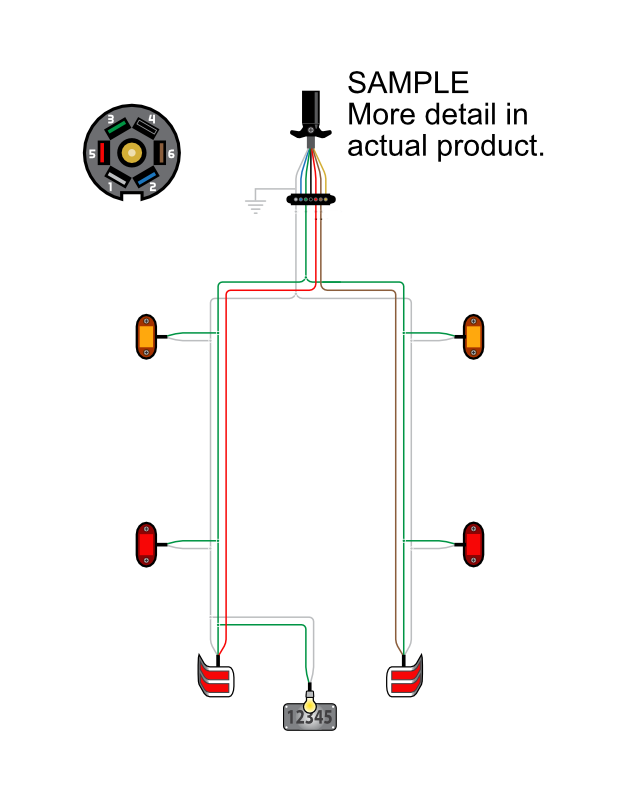

A Reliable Wiring Harness

Quality Parts Matter

“Trailer wiring shouldn’t suck.” – Mark

Weatherproof

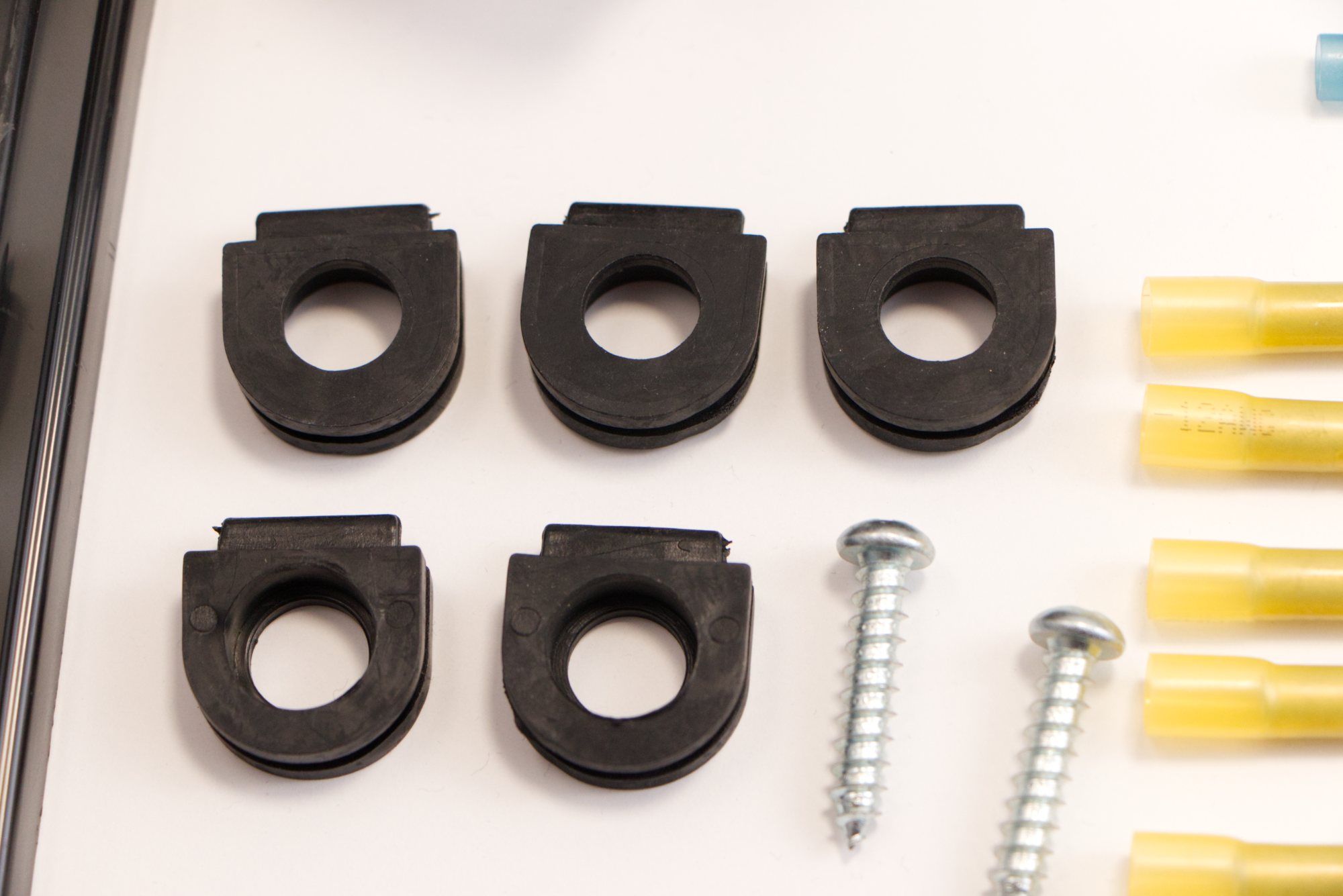

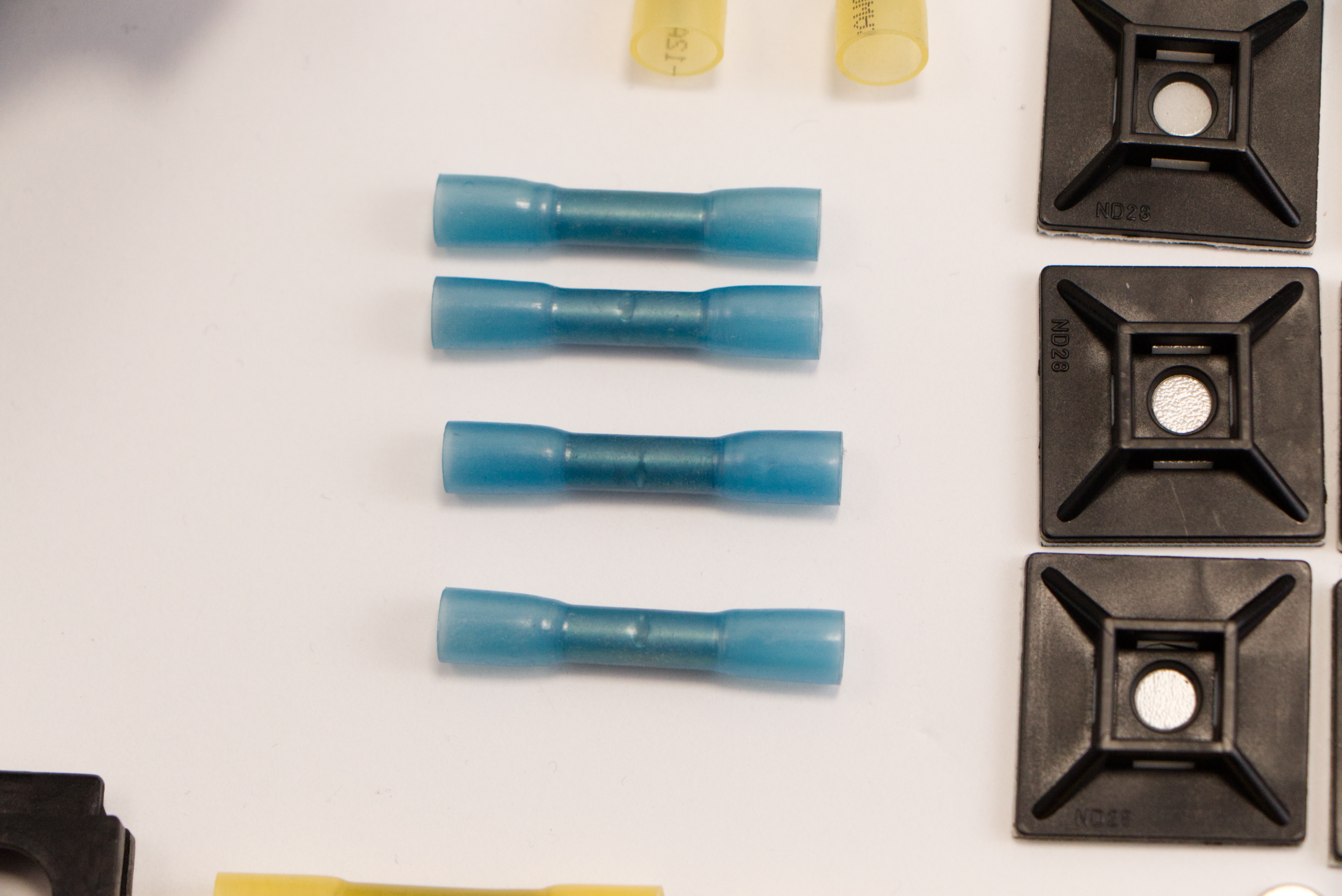

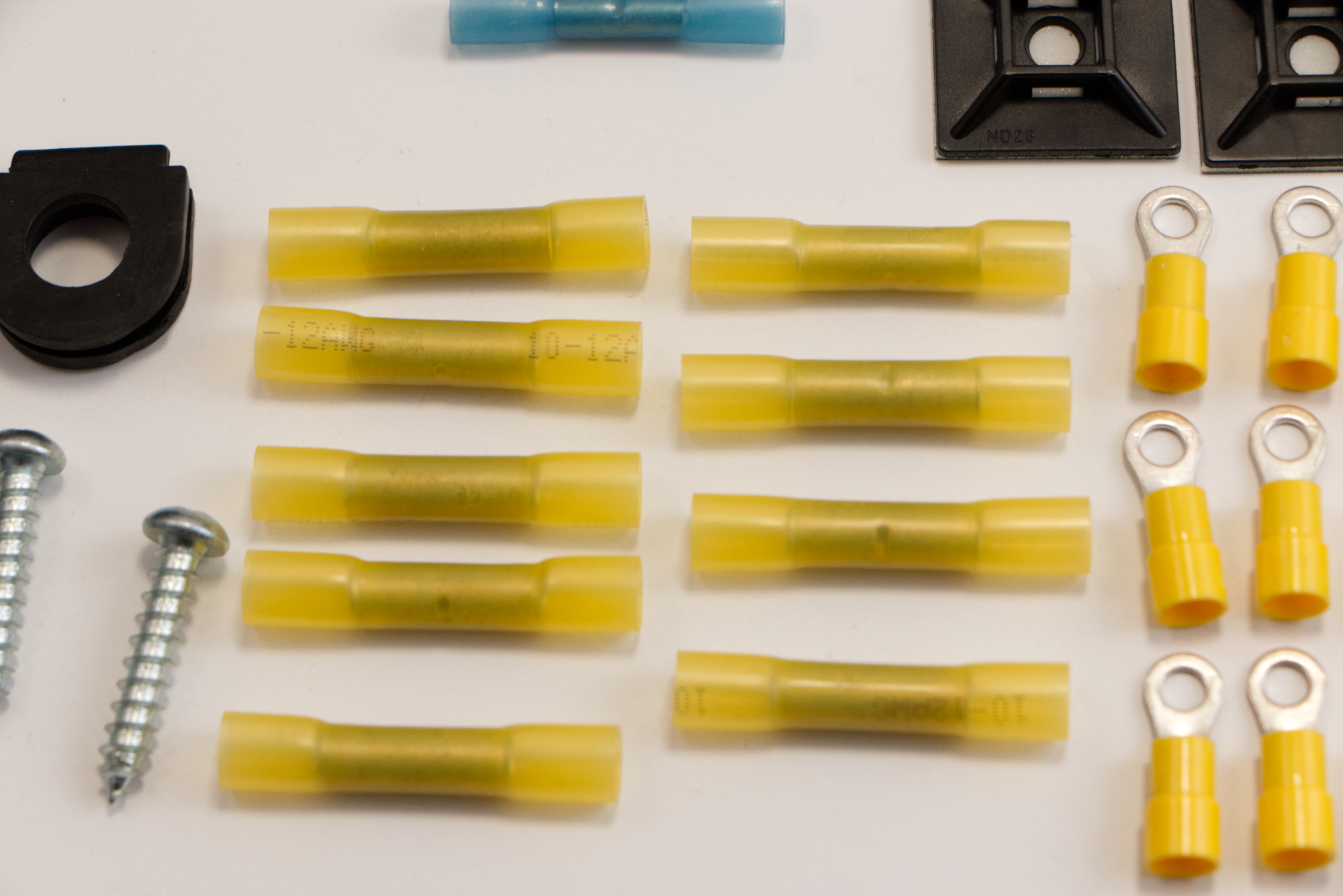

From the junction box, butt connectors, and wire sheath, this trailer wiring harness is designed to be as waterproof as possible.

Quality

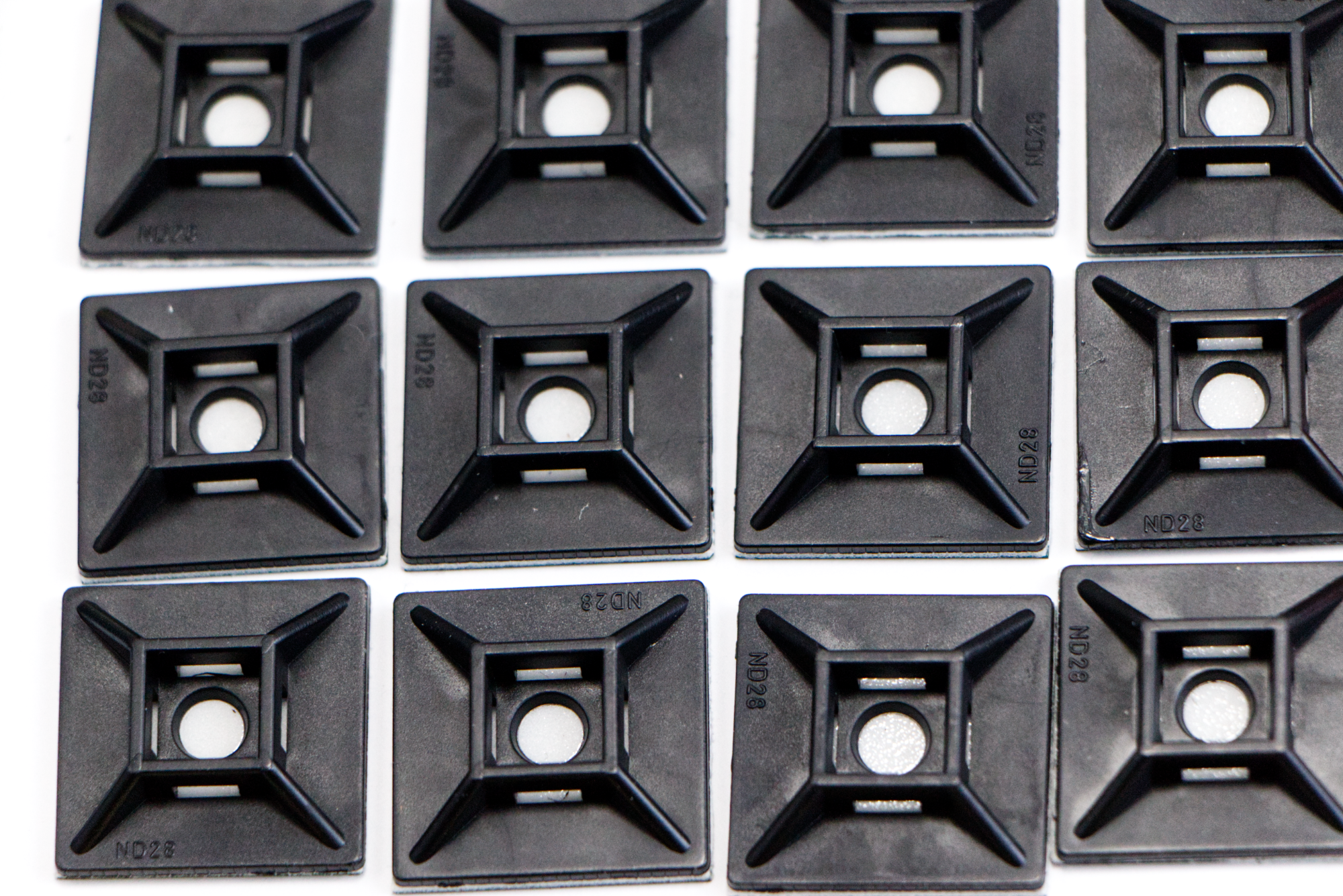

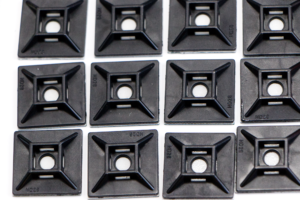

Pure Copper Wire (Made in USA), heat shrink connectors, an 8 foot durable 7-blade RV plug, harsh environment wire mounts, loom and zip ties.

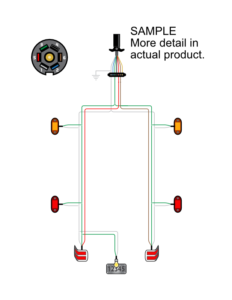

Flexible Installation

Multiple wiring harness sizes to fit your DIY teardrop trailer build. All with the same quality parts.

Reviews

There are no reviews yet.