By the end of this article, you will have started your design for a custom welded DIY teardrop trailer frame.

The best frame for a teardrop trailer is one that is designed for one purpose – a teardrop trailer. There are a variety of different frames that people use for teardrop campers (read more about those frames). A custom-built trailer frame offers the best opportunities for creativity, longevity, and long-term cost savings for your teardrop trailer.

However, it can feel overwhelming to take on such a project -which is why so many people don’t do it. That’s why we’re here!

It’s quite simple to design a long-lasting welded trailer frame in these SIX steps.

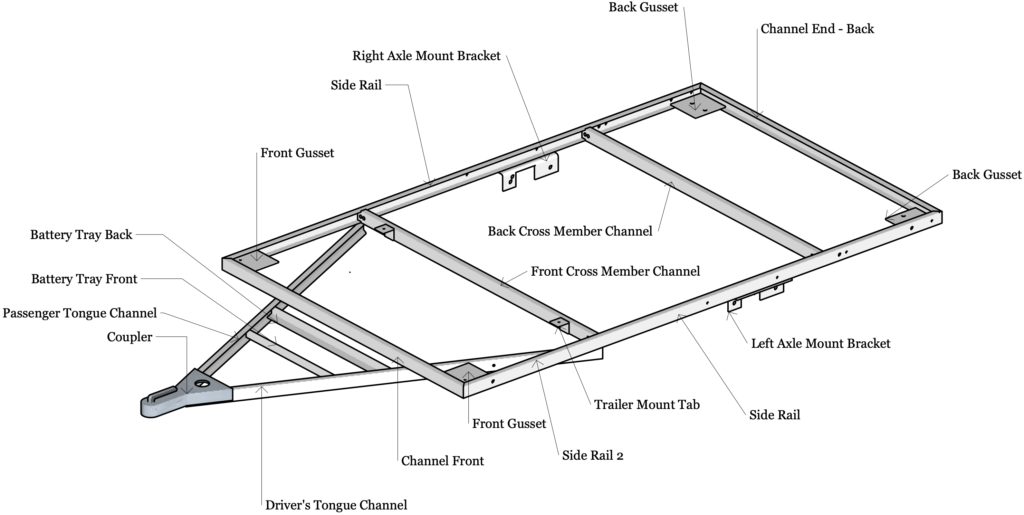

With any custom build, there are a variety of requirements that need to be built in to the trailer frame design. However, the core design elements for most teardrop frames fall into one of six categories:

When you’re eyeballs deep in a fabrication job, the last thing you need is to design or problem solve. Remove resistance to the assembly process by making design decisions in a drawing before striking the first spark of steel. It will save you money, time, and frustration.

There are two ways that builders draw the teardrop frame:

The right type of steel for the frame makes the trailer function properly, saves overall weight while keeping the strength required for your teardrop’s intended use (determined in Step 1). Refer to the requirements in Steps 1 – 2 to help determine what type of steel you’ll need.

The two most common steel shapes in teardrop trailer frames:

Consider the thickness of the steel that is required. A local welder or steel supplier can offer professional advice specific to your project but most teardrop camper frames are between 1/8″ – 3/16″ thick material. More than 1/4″ is certainly excessive -even for an offroad teardrop.

Just because steel comes in a wide variety of shapes (tube, channel, angle, flat stock, round stock) doesn’t mean your trailer frame should use them all. Ideally, your frame will have 3 – 5 different shapes for two reasons:

The key is to know how much you need of each type.

Mapping out each cut for the most efficient use of the material is vital for saving money and minimizing waste.

A free and easy way to map out all of your cuts (while accounting for blade width) is CutListOptimizer.com. The site will calculate the most efficient cut list for your raw materials and give you an image map of the cuts and a written list of the cuts.

Now that you have your plan mostly determined, it is time to bring the steel experts to polish it. They can help you source materials, critique your design, and even do some of the work!

There are three professionals that I always seek out when designing a new DIY teardrop frame.

Depending on where you live, you’ll want to contact your local transportation authorities to get a list of requirements for a homebuilt trailer frame. Usually, this information is buried on a government website. If you design with the government requirements in place, then it should pass inspection and be authorized for use on public roads.

Take your drawing and requirements to a local welder and ask for their feedback. This person can also direct you to the best places to source the raw steel or the best paint/powdercoater in the area (they are NOT all the same).

Steel suppliers can help you get the exact materials you need. It is worth asking them about any cut offs they may have stockpiled from other customers. They usually sell those at a discount or, at the very least, it could save you from having to buy a full length of steel. They may also be able to offer a similar shape of steel at a better price if you’re willing to adapt your design just a bit.

Now that you have the pros on your side, its time to make your steel order and get ready to make your frame!

Take an inventory of your safety gear and tools for metalworking. The critical safety gear is long sleeves, ear protection, eye protection, and gloves. The critical tools that you’ll need are a welder and an angle grinder.

Check out the Expert Tips lessons for a much more exhaustive list of tools and safety gear.

I have a friend named Bill who is a professional welder. He is always telling me that metalwork is much easier than woodwork.

In his words, “If I cut something too short I can always add material back. That’s easier than woodwork!”

He’s right. Even if you do all 6 of these design steps and you find you’ve fallen short of what you need, it’s easy to just add or subtract to your frame. Metalwork allows us to try many times to get it just right.

Take it from Bill and me, you can design a great teardrop trailer frame with these 6 steps and a little professional feedback.

Cheers!

Mark

AFFILIATE PROGRAM